Uncategorised

Drying Racks Into Action

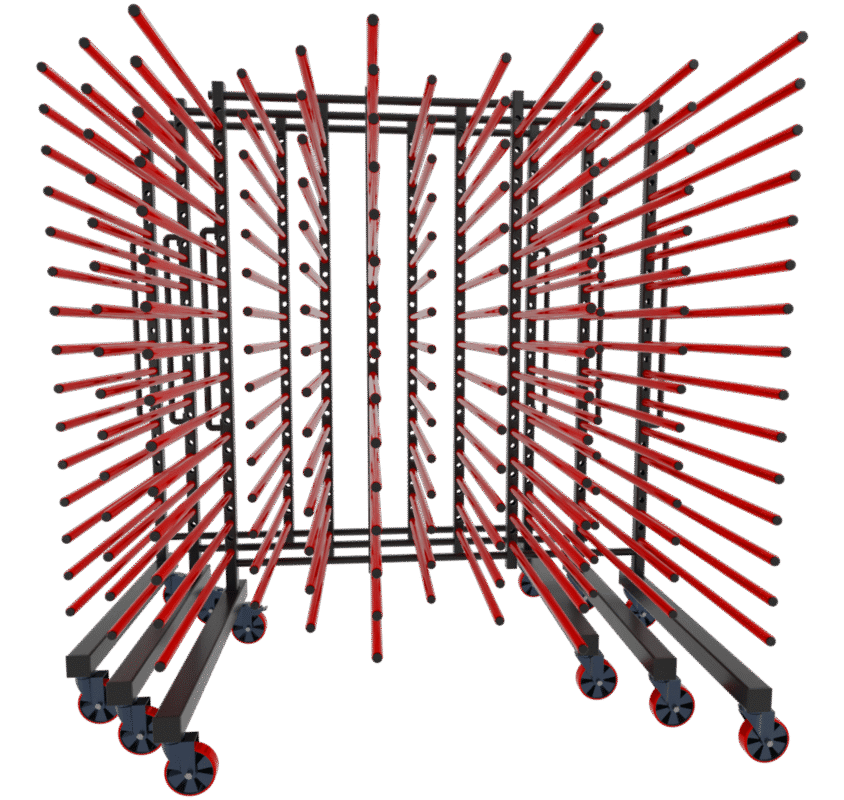

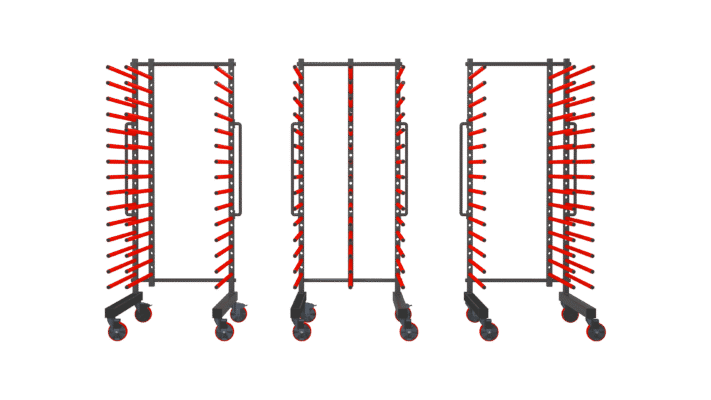

Racks into action isn’t just a phrase, it’s a movement toward more intelligent, more efficient workflows in demanding industries like woodworking, metal, aerospace, automobile, and textile. Each of these industries deals with unique daily challenges that impact productivity and product quality. Our rack systems are engineered to address these pain points head-on, delivering practical, innovative solutions tailored to your specific operations.

Common Industry Problems

Across all industries, some consistent issues appear in current rack systems:

- Scratches and surface damage during storage or transport.

- Back paint transfer from dirty holding bars

- Incompatibility with various part sizes—either too wide or too narrow.

- Structural instability, causing shaking or tipping during movement.

How We Solve Them

Our modular, steel-structured rack systems are built with industry demands in mind:

- Heavy-duty steel frame ensures durability and stability.

- Rubber-coated holding bars prevent scratches and paint marks.

- Adjustable holding arms accommodate narrow and wide parts without bending.

- Central post design allows part-width flexibility on demand.

- Removable arms provide room for oversized or thick items.

- Available in up to 12 ft. length, ideal for extra-long parts.

- Rolls easily on industrial floors, even with heavy loads.

- 3-inch vertical spacing between arms—the widest in the market.

Industry Applications

Woodworking

From CNC to Edge processing and Spray booth to assembly Dept, woodworking parts need safe handling during drying and transportation. Our racks adapt to different lengths and widths, roll smoothly between production lines, and protect finished surfaces.

Metal Industry

Heavy and sharp-edged parts require high load capacity and secure movement between cutting, welding, and assembly areas. Our solution eliminates rack bending and protects finishes during transport.

Textile

Large rollers or fabric bolts need customized support and smooth transport. Our racks can be configured for roller storage and are easy to maneuver in busy production spaces.

Aerospace

Precision parts with tight tolerances must remain scratch-free and aligned. Our rubber coating, tight arm spacing, and structural integrity ensure damage-free movement.

Automobile

During coating, drying, or component assembly, automobile parts demand space, flexibility, and strength. Our racks allow adjustable spacing and secure long, heavy items without shaking.

Bottom Line: Don’t settle for generic rack systems that barely meet your needs. With our customizable, industry-ready solutions, you get equipment that works as hard as you do. Whether it’s drying, transporting, or storing, put your racks into action and experience the difference.

Need help selecting the right rack for your operation? Contact us today for tailored solutions built for your industry.