Uncategorised

How to Choose the Right Drying Rack

How to choose the right drying rack is one of the most important decisions for any manufacturing, woodworking, or finishing facility. The right rack increases efficiency, protects finished products, and helps manage space better. Choosing the wrong one, on the other hand, can lead to damaged parts, wasted time, and lost productivity. Here’s how to make the right choice by focusing on the most important criteria:

1. Understand Your Part Sizes

Every manufacturer produces parts in different dimensions. Whether you’re drying cabinet doors, drawer boxes, panels, or moldings, your drying rack should accommodate your parts safely and efficiently.

- Minimum Width: Ensure that the width between the holding arms can support your smallest parts without letting them tip or fall.

- Maximum Width: Likewise, your rack must be wide enough to hold your longest parts securely, without risk of bending or imbalance.

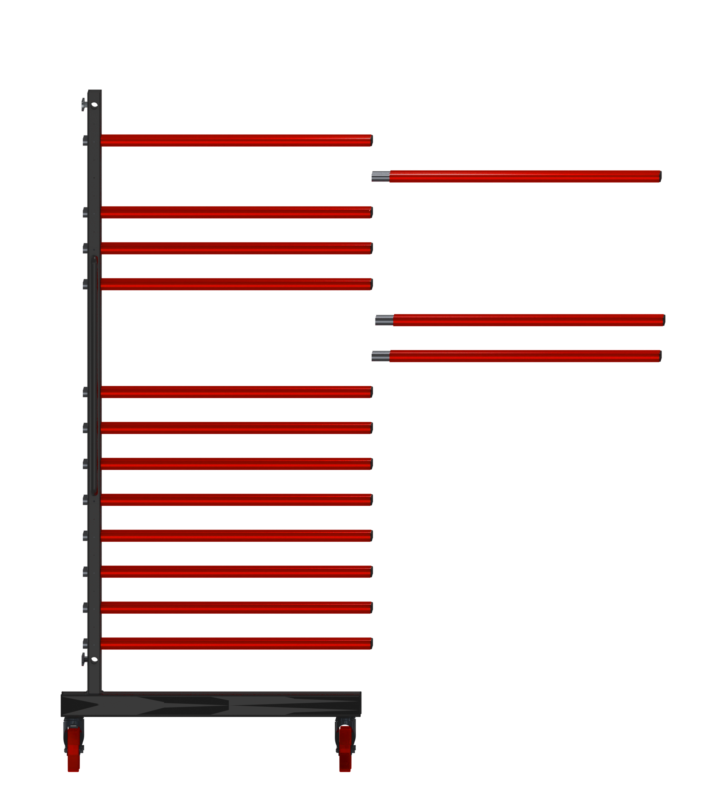

- Part Thickness and Spacing: This is one of the most overlooked yet critical features. If your parts are thicker than the standard spacing, they risk getting scratched or pressed against each other. At FlexiRacks, we solve this by offering adjustable spacing and removable holding bars, allowing thicker parts to be loaded easily without damage.

- Rack Width Options: Depending on your product line, you may need:

- 30-inch wide racks for smaller or medium-sized parts

- 60-inch wide racks for larger components or higher part volume

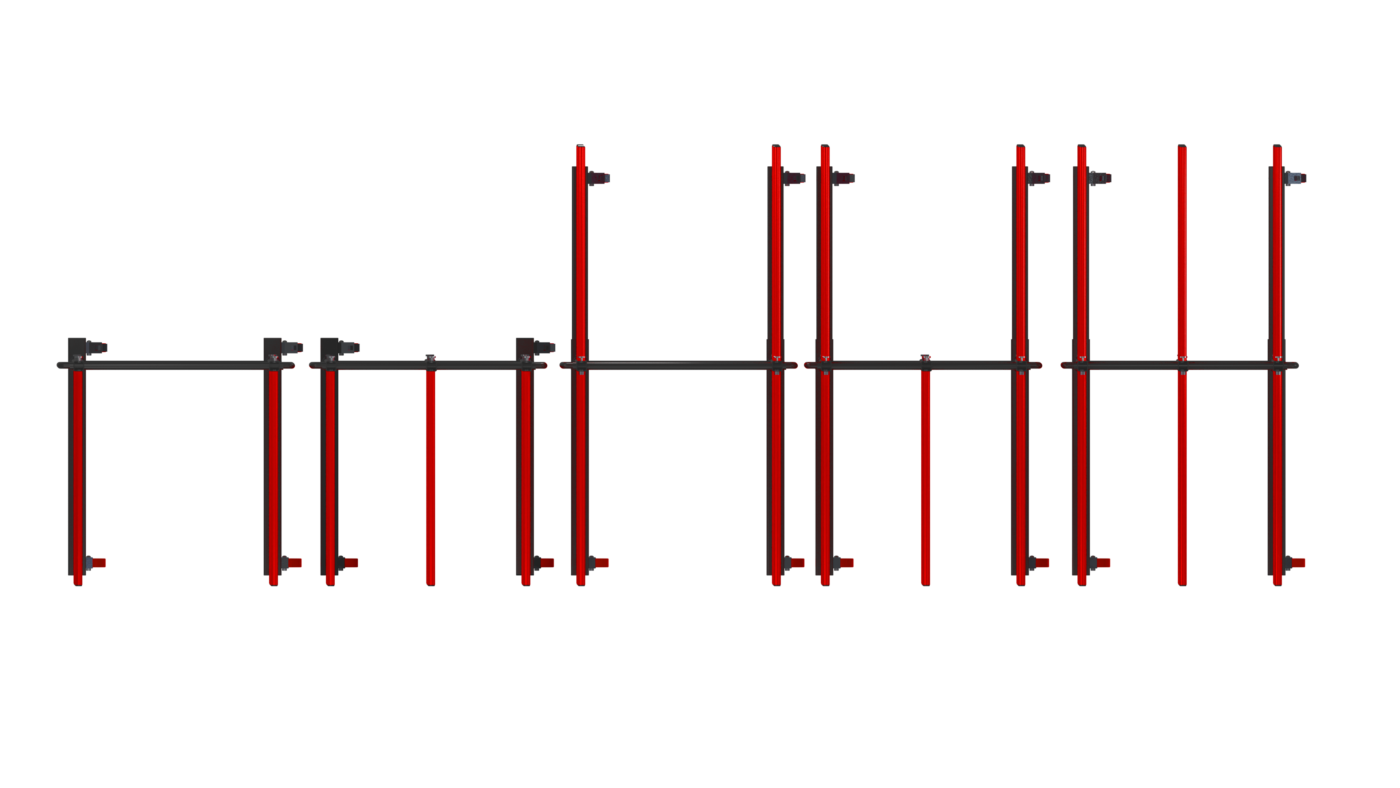

- For Long Molding Parts: If you need to handle long, narrow moldings, our racks can be connected end-to-end with a 30-inch connector, which allows you to create a custom, extended rack that holds parts up to 180 to 240 inches in length without bending or sagging.

2. Plan for Current and Future Capacity

Do you finish 100 parts a day or 300? Will this number grow next year?

- Each drying rack can hold 15 to 60 parts per side, depending on the design.

- For single-sided racks, plan based on your daily production and drying cycle.

- If you’re applying multiple coats with 15–20 minutes of dry time between each, calculate how many parts you’ll need drying at once.

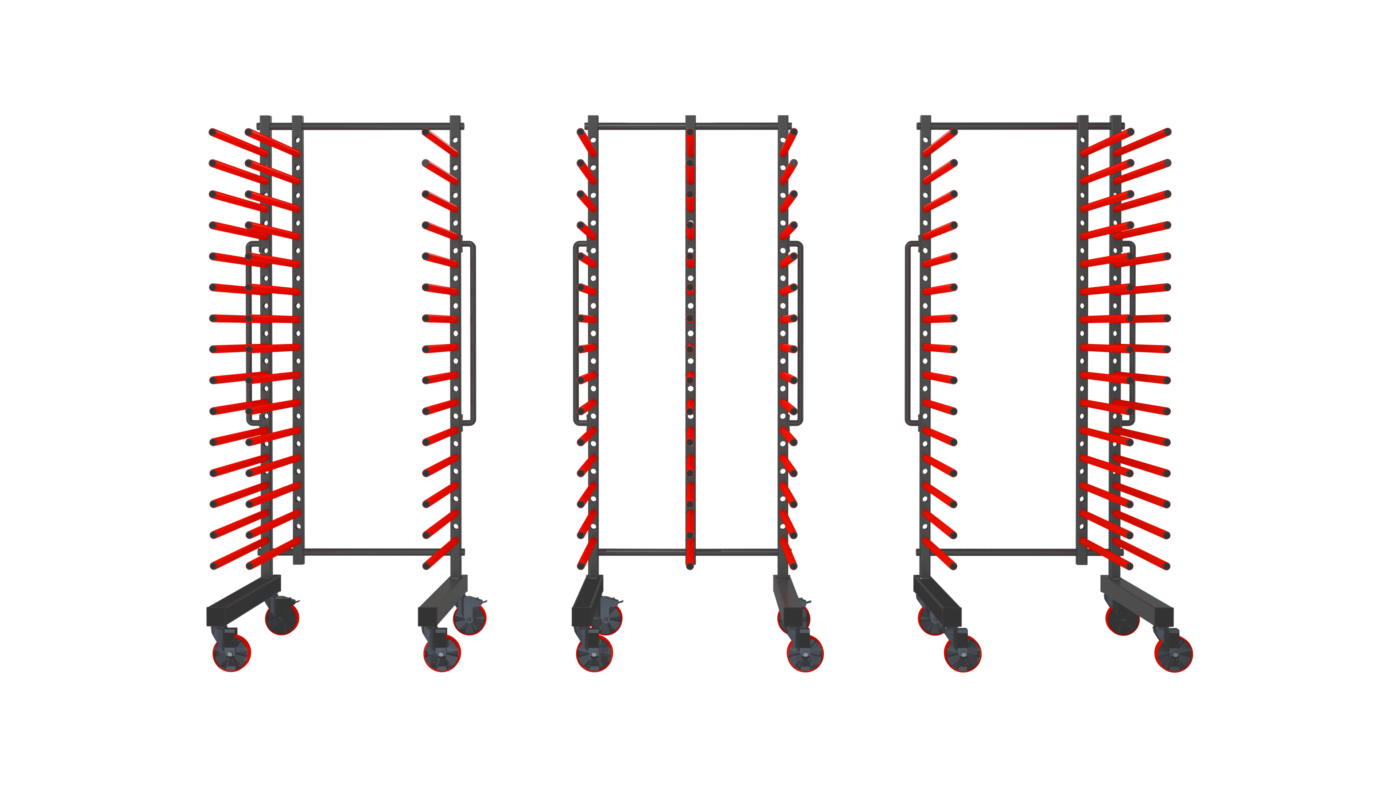

- If needed, upgrade to double-sided racks to double your capacity without doubling your footprint.

Example:

If you finish 300 parts daily, and each takes 15 minutes to dry, and your working day is 8 hours,

You’ll need racks that can cycle parts efficiently without delays. Based on the finish and drying rotation, quick calculation helps you determine how many racks are required.

“Good Scenario with calculation is mentioned at the end.”

3. Check Load Limits and Durability

Weight is another key factor. Consider:

- Maximum load per level

- Total load per rack

Overloading can create safety risks and warp your racks. At FlexiRacks, we clearly rate every level for safe heavy-duty use, but if your use case requires more, we offer custom solutions tailored to your needs.

4. Prioritize Holding Arm Protection

One of the most common complaints we’ve seen during our visits to shops and facilities is part damage from rough holding arms. Customers consistently emphasize the importance of a smooth, coated finish on these arms to prevent scratches or marks on freshly finished parts.

FlexiRacks uses protective coatings that are easy to clean and safe for delicate finishes, giving you peace of mind during the drying process.

5. Don’t Forget Storage Efficiency

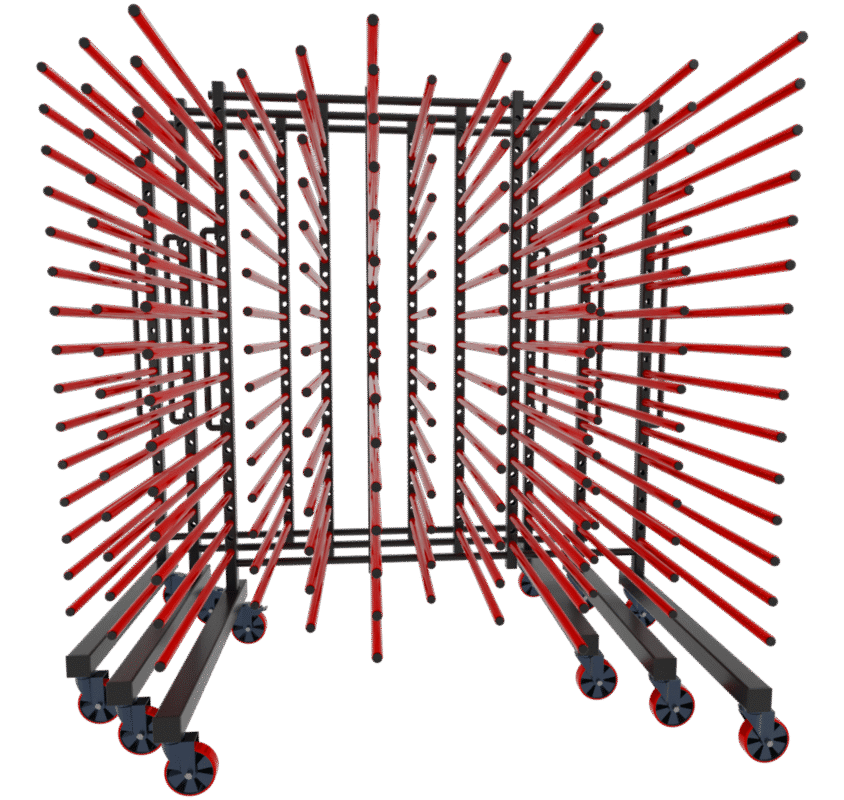

When racks are not in use, space becomes an issue, especially in small shops. This is where stackability and nested storage make a huge difference.

FlexiRacks are designed to fit into one another, minimizing the square footage needed to store multiple units when idle. This smart feature helps you maintain a clean and organized workspace, no matter the size of your facility.

Final Thoughts

Choosing the right drying rack requires a good understanding of your parts, production flow, capacity needs, and workspace limitations.

With FlexiRacks, you don’t need to compromise. Our modular design, customizable configurations, and thoughtful features like adjustable spacing, expandable capacity, and protective arms give you a solution that grows with your business.

Have questions about the best rack for your workflow? Our team is here to help you select a solution that fits both your needs and your space. Reach out today and experience the FlexiRacks difference.

Example: Choosing the Right Number of Racks Based on Daily Output

To determine how many FlexiRacks you need, let’s break down a typical production day:

- Total parts finished per day: 300 parts

- Drying time per part: 15–20 minutes

- Working hours per day: 8 hours = 480 minutes

- Rack configuration:

- Each rack side holds 15 positions

- Double-sided racks = 30 parts per rack

Important Note on Rack Capacity

This calculation assumes you’re loading one part per holding arm, which is typical for oversized items. However, since each holding arm is 30 inches long, you can easily fit two smaller parts side-by-side on one arm, especially if the parts are narrow or lightweight.

This effectively doubles the number of parts per side to 30, and up to 60 per rack with a double-sided setup, significantly boosting capacity without extra floor space.

Step 1: Determine how many parts can be dried per position per day

Assume a drying time of 20 minutes per part:

- 3 drying cycles per hour → 24 drying cycles per 8-hour shift

- So, each drying position = 24 parts/day

Step 2: Calculate the number of drying positions needed

You have 300 parts to dry, and each drying position can process 24 parts per day:

- 300 ÷ 24 ≈ 12.5 positions, rounded up to 13 positions

Step 3: Determine how many racks you need

Now, calculate how many racks it takes to provide 13 drying positions, depending on how you’re using them:

For oversized parts (1 part per arm):

- Single-sided rack (15 parts)

→ 13 ÷ 15 = ~0.87 → You need 1 rack (rotated every 20 minutes) - Double-sided rack (30 parts)

→ 13 ÷ 30 = ~0.44 → You need 1 double-sided rack

For smaller parts (2 parts per arm):

- Single-sided rack (30 parts)

→ 13 ÷ 30 = ~0.44 → You need 1 single-sided rack - Double-sided rack (60 parts)

→ 13 ÷ 60 = ~0.22 → You need 1 double-sided rack

If You Want to Dry All 300 Parts at Once (No Rotation):

- Single-sided racks (30 parts)

→ 300 ÷ 30 = 10 racks - Double-sided racks (60 parts)

→ 300 ÷ 60 = 5 racks

Recommendation

Your rack count depends on whether you plan to rotate parts throughout the day or dry all at once:

- With part rotation:

1–3 double-sided racks (depending on part size) - Without rotation:

5–10 racks (depending on layout and part size)