Products Features

Space-Saving Drying Racks for Small Storage Areas

Space-saving drying racks are becoming an essential need in today’s fast-paced manufacturing and production environments. Whether you’re a small woodworking shop or a large-scale manufacturer, storage space is always at a premium. At FlexiRacks, we understand that when racks are not in use, they shouldn’t get in your way. That’s why we designed our racks to fit into each other, creating an efficient, low-footprint storage solution that keeps your workspace organized.

The Storage Struggle Is Real

Ask any shop manager or warehouse operator, and they’ll tell you that floor space is one of the most valuable resources. Equipment that sits unused but still takes up room adds clutter, slows operations, and can even create safety hazards. This is especially true for drying racks, which often need to be available when production is high but remain idle during off-peak times.

Traditional drying racks can be bulky and static. Even when not holding parts, they often remain fully extended, taking up the same amount of space as they do during operation. Over time, that wasted space adds up, and you may find yourself storing idle racks in inconvenient corners or even moving them off-site, both of which waste time and increase operational inefficiency.

The FlexiRacks Solution

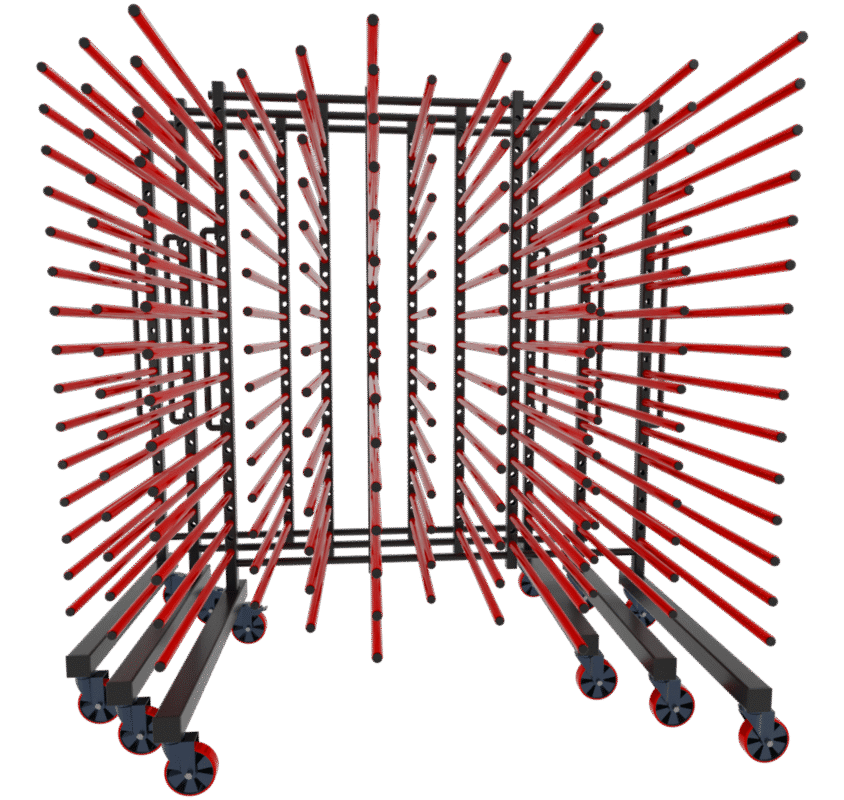

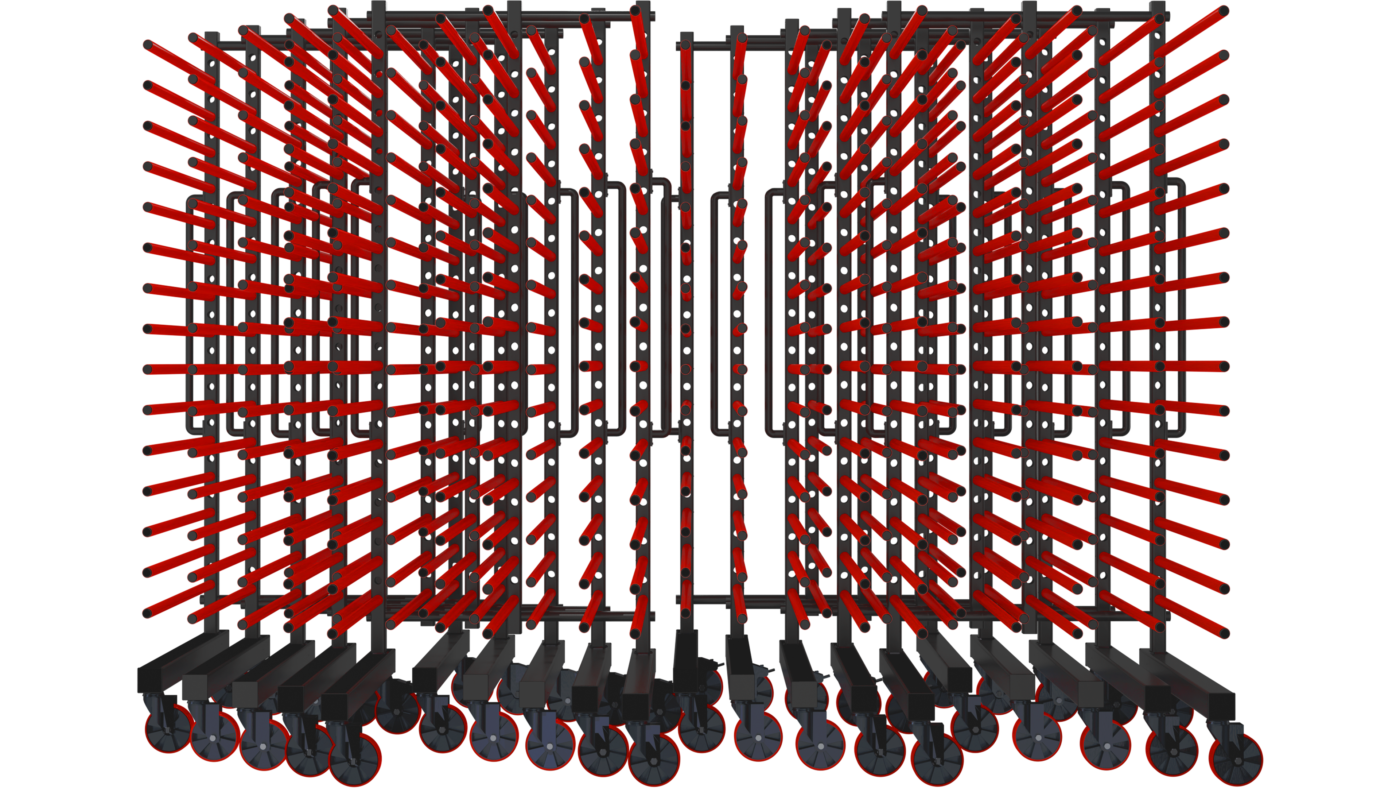

FlexiRacks offers a smart alternative: modular drying racks designed to nest together. Our racks are built with a stackable, interlocking design that allows one rack to slide partially or fully into another. The result? A clean, organized storage footprint that’s a fraction of the total expanded space.

Whether you’re storing two or ten racks, you’ll reclaim precious square footage that can be used for production, packing, or safe movement of materials. This is a game-changer for shops with limited space or those sharing floor space between departments.

How It Works

When you’re finished using a FlexiRack unit, you can:

- Nest one rack inside another, aligning structural features for a compact fit.

- Store multiple racks in a footprint that’s no bigger than a single unit.

No heavy lifting or complicated folding mechanisms are involved. The design is intuitive and efficient, allowing workers to handle the racks without special tools or training.

Real-World Benefits

Here’s how customers are making the most of FlexiRacks’ space-saving design:

- Small shops with limited square footage use the nesting feature to keep floor space open when drying isn’t needed.

- Multi-department facilities rotate drying racks between areas and can store unused racks without cluttering walkways.

- Seasonal manufacturers store racks between production runs without renting external storage units.

One customer in the cabinetry industry reduced their off-season storage footprint by over 60% simply by switching to FlexiRacks. Another customer appreciated how quickly their staff could “clean up” the workshop floor by compacting idle racks after each shift.