Products Features

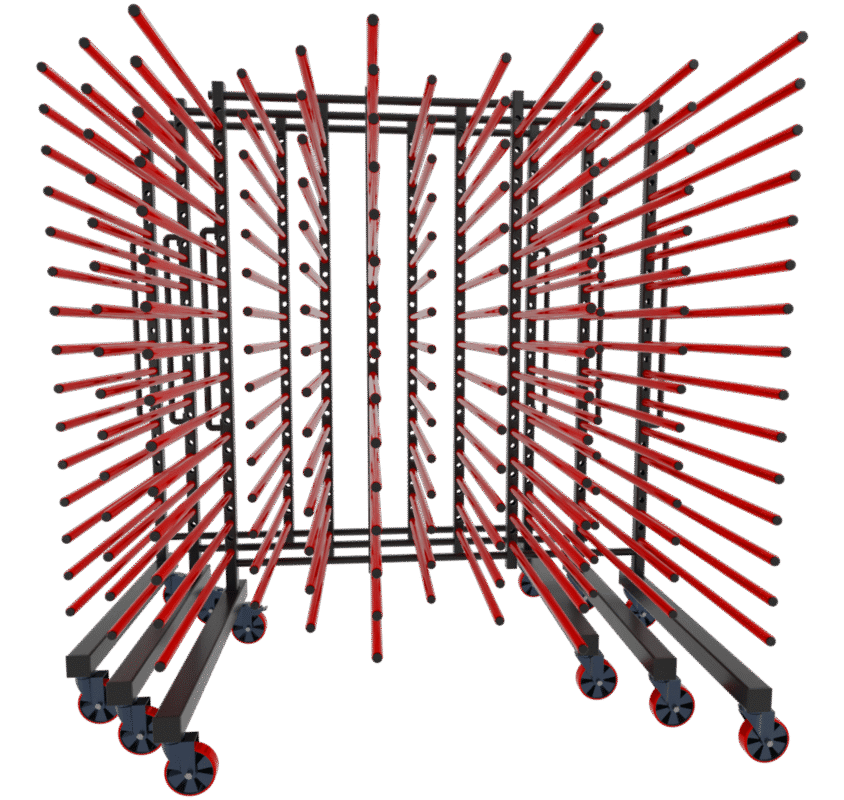

Rack Vertical Spacing Adjustment: A Smarter Way to Load Thicker Parts

In many industrial environments, rack vertical spacing adjustment has become a critical feature for improving efficiency and protecting valuable parts. Industries such as woodworking, automotive, and aerospace often handle products of varying thickness that require flexible racking systems for drying, storage, or transportation.

Unfortunately, many racks in use today lack this flexibility. With fixed or narrow vertical spacing, users are unable to load thicker components, like drawer boxes or bulky assemblies, without risking damage or wasting floor space. A lack of rack vertical spacing adjustment can hinder productivity, limit capacity, and increase overall clutter in the workspace.

The Challenge: Fixed Vertical Space between holding bars = Limited Productivity

Traditional drying or storage racks often have fixed spacing between arms or shelves. While this may be suitable for uniformly sized components, it quickly becomes problematic when dealing with thicker items like drawer boxes, stacked parts, or wide edge-banded panels. In the worst-case scenarios, valuable parts are left leaning against walls or stacked unsafely on workstations, simply because the rack cannot accommodate their size. This not only creates clutter but also poses safety hazards and slows down production lines.

In worst-case scenarios, valuable parts are left leaning against walls or stacked unsafely on workstations, simply because the rack can’t accommodate their size. Not only does this create clutter, but it also poses safety hazards and slows down production lines.

Our Solution: Adjustable Rack Vertical Spacing Adjustment for Total Control

This is where FlexiRacks’ Spacing Adjustment feature makes a real difference.

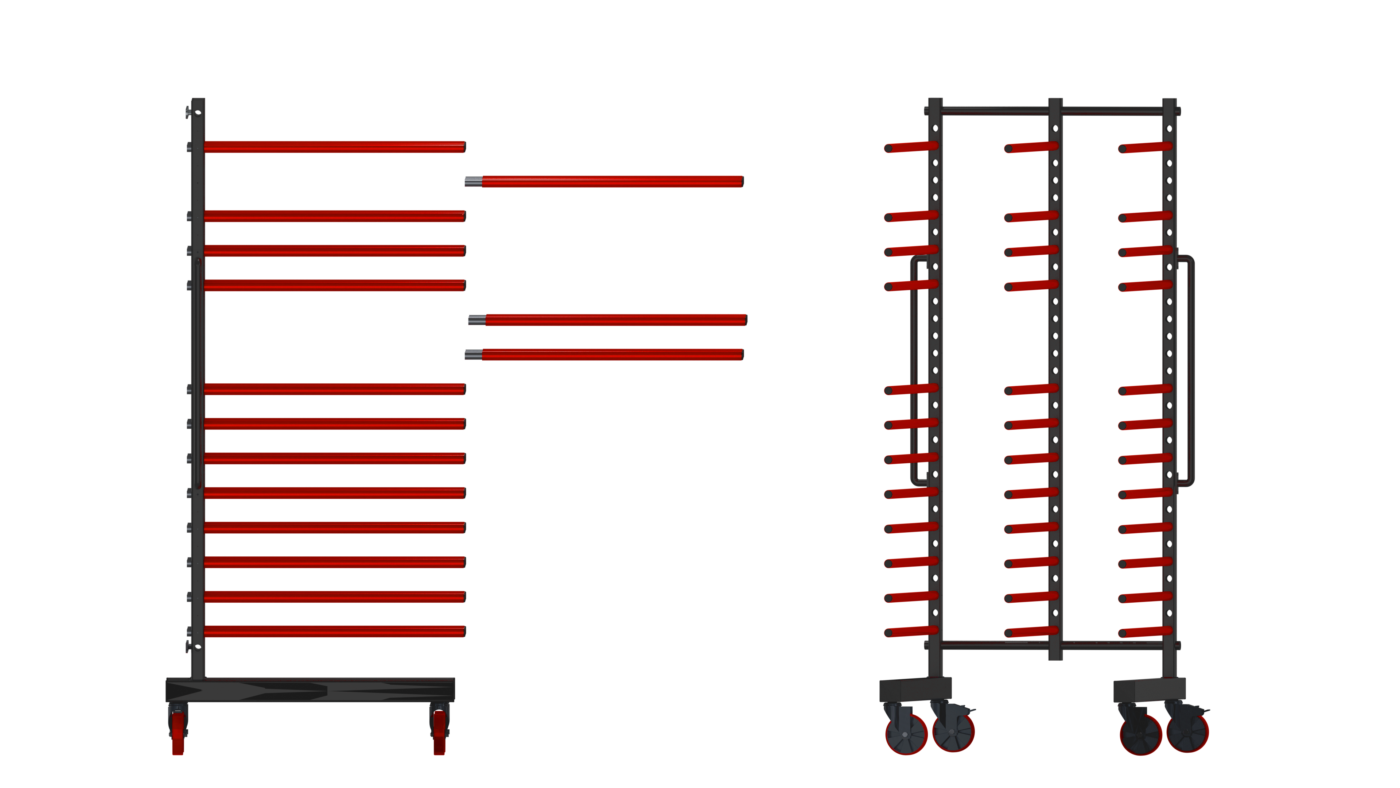

Each holding bar on our racks can be repositioned—or completely removed—to instantly create more vertical clearance for thicker items. Do you need to load tall drawer boxes or larger parts? Simply remove a bar and gain up to double the vertical space within seconds. No extra equipment. Just smarter design.

Our adjustable design empowers users to:

- Customize the spacing between holding arms for various part sizes

- Quickly adapt the rack for small or large batch production

- Improve airflow around drying items for better curing

- Safely support larger or heavier parts without damaging finishes

Designed for Real-World Use

Whether you’re working with:

- Drawer boxes

- Stair steps

- Assembled units

- Wood panels

…our Rack Vertical Spacing Adjustment system gives you the flexibility you need to keep production moving smoothly.

The Result: Space Optimization Meets Workflow Efficiency

By eliminating the rigid structure of fixed-height shelving, FlexiRacks allows you to maximize every inch of your rack. You’re no longer forced to work around the system. Instead, the system adapts to your workflow, helping you:

- Save space

- Improve shop organization

- Speed up turnaround time

- Protect high-value parts from damage

Conclusion:

Rigid racks belong in the past. With FlexiRacks’ Spacing Adjustment feature, you’re equipped with a smarter, safer, and more scalable solution that evolves with your production needs. Say goodbye to wasted rack space—and hello to better control, cleaner floors, and faster operations.